What is Passivation?

According to ASTM A380, passivation is "the removal of exogenous iron or iron compounds from the surface of stainless steel by means of chemical dissolution, most typically by a treatment with an acid solution that will remove the surface contamination, but will not significantly affect the stainless steel itself."

In addition, it also describes passivation as "the chemical treatment of stainless steel with a mild oxidant, such as a nitric acid solution, for the purpose of enhancing the spontaneous formation of the protective passive film."

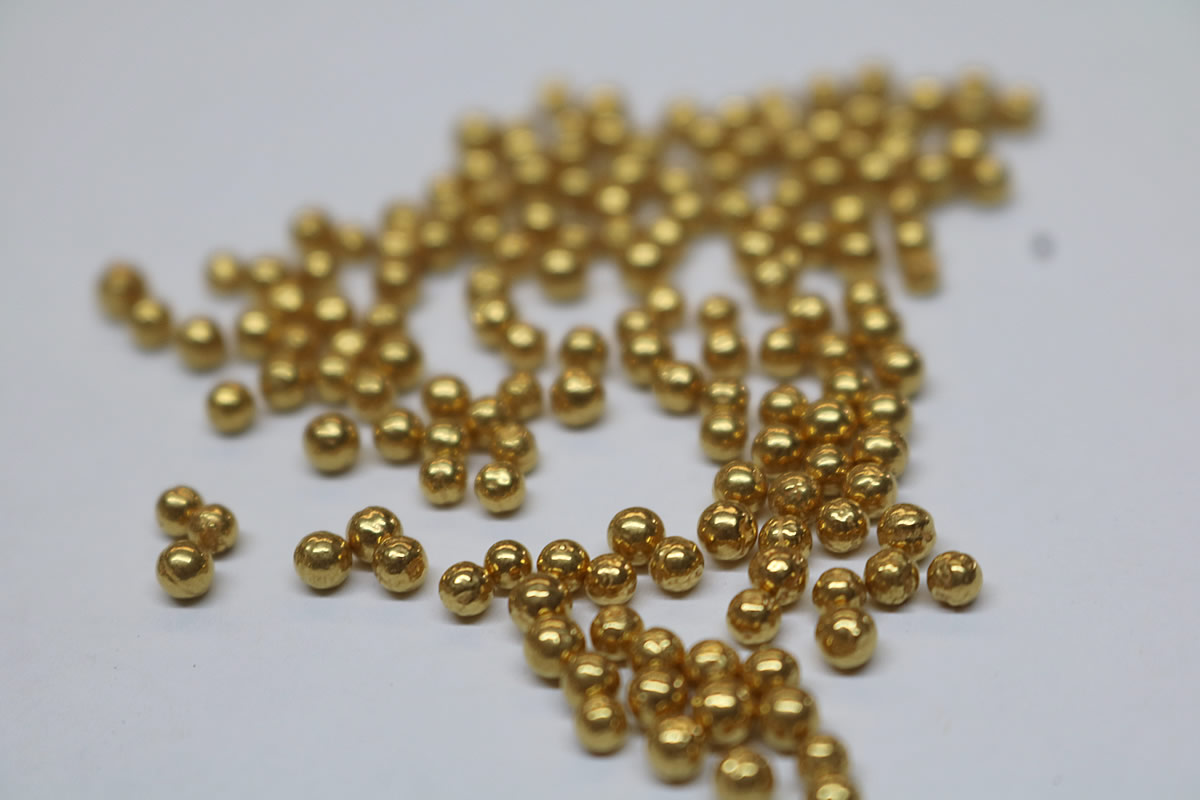

Passivation removes free iron

In lay terms, the passivation process removes "free iron" contamination on the surface of stainless steel from machining and fabricating. These contaminants are potential corrosion sites that result in premature corrosion, and ultimately result in the deterioration of a component if not removed. In addition, the passivation process facilitates the formation of a thin, transparent oxide film that protects the stainless steel from selective oxidation (corrosion). So what is passivation? Is it cleaning? Is it a protective coating? It is a combination of both.

Oxidation of stainless steel?

This invisible free iron film can be the result of improper cleaning from the mill, contamination from storage, or, in the case of finished components, traces originating from grinding and machining tools used in manufacturing. As these tools wear, metal particulate are being transferred to, or embedded in the surface of stainless steel parts.

Although the iron is not visible to the naked eye, when exposed to adverse atmospheric conditions, such as high humidity, it results in detrimental oxidation of stainless steel components. Sulfides are another contributing factor for corrosion. Sulfur is added to some alloys to increase machinability. If not removed prior to service, the Sulfur can initiate sites for localized corrosive attacks.

Immunize the component

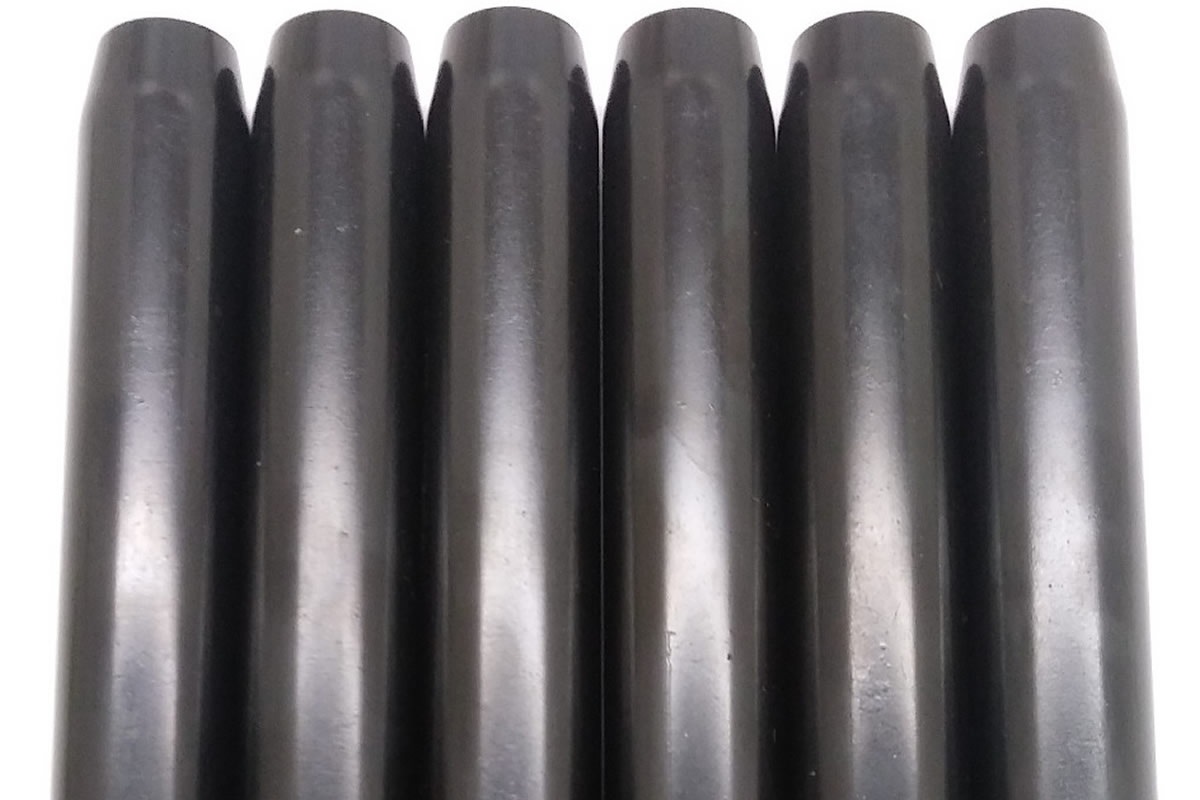

To remove free iron or sulfides from the surface of a part, surface finishers passivate (immunize) the component using a variety of different solutions containing nitric acid and oxidizing salts.

By adjusting the concentration, dwell time, and temperature of these cleaning baths, the iron or sulfides are dissolved without stock removal of the substrate alloy. The 300 Series, 400 Series, and Precipitation-Hardening (P.H.) stainless steels all require different bath conditions for optimal removal of these trace elements.

Passivation is inexpensive

Passivation (immunization) is used in a variety of industries to include aerospace fuel system controls, medical implants, marine fasteners, and drive components for computers. In any application where corrosion resistance is important to function, passivation should be considered. The use of passivation is relatively inexpensive and enhances the life of the component.

Contact Us

We want to hear from you.

Contact Plating Solutions today

and send us your questions and comments!